Call: 08071793358

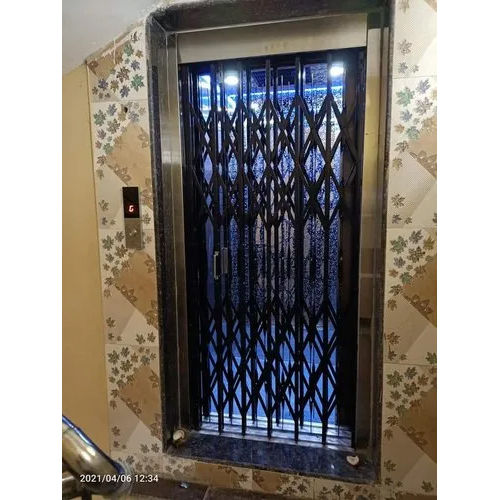

Industrial Goods Lift Maintenance Service

Price 2500 INR/ Unit

MOQ : 1 Unit

Industrial Goods Lift Maintenance Service Specification

- Load Capacity

- Up to 3000 kg

- Pit Depth

- Minimum 1000 mm

- Usage

- Industrial Cargo/Hospitality/Factory/Storage

- Noise Level

- < 65 dB

- Hoist Way Size

- Customized as per lift design

- Machine Room Size

- Required (for traction type)

- Voltage

- 380 V / 415 V, Three Phase

- Door Opening Size

- Up to 2000 mm

- Type

- Goods Lift, Vertical Freight Elevator

- Car Dimension

- Customizable (Up to 2300 mm x 2000 mm)

- Inclination

- Vertical only

- Overhead Height

- Minimum 4500 mm

- Material

- Mild Steel / Stainless Steel

- Drive Type

- Hydraulic / Traction

- Power Supply

- 3-Phase AC

- Speed

- 0.15 m/s to 0.5 m/s

- Max. Lifting Height

- Up to 30 meters

- Max. Lifting Weight

- 3000 kg

- Mechanism Type

- Hydraulic / Traction driven

- Working Temperature

- -10C to +50C

- Control Device

- Microprocessor based controller

- Safety Device

- Emergency Stop, Overload Sensor, Door Interlock

- Capacity

- 500 kg to 3000 kg

Industrial Goods Lift Maintenance Service Trade Information

- Minimum Order Quantity

- 1 Unit

- Main Domestic Market

- Delhi

About Industrial Goods Lift Maintenance Service

Unlock reliable performance for your industrial lifts with our world-class Goods Lift Maintenance Service, crafted to meet the needs of factories, warehouses, and logistics centers. Highlighted by 24x7 service availability and a venerable reputation for rapid response, our certified engineers ensure your lifts operate at peak efficiency, adhering strictly to ISO 9001 and IS Standards. Benefit from meticulous monthly, quarterly, or on-call maintenance, detailed service logs, manual emergency rescue operation, and noteworthy spare parts supply. Grab yours todaysecure seamless operations, safety, and longevity for your vertical freight elevators, supporting loads up to 3000 kg and lifting heights up to 30 meters.

Diverse Applications & Exceptional Usage

Our Industrial Goods Lift Maintenance Service is ideal for a broad spectrum of sectorslogistics warehouses, factories, storage facilities, and hospitality environments. Highlighted applications include seamless vertical transportation of heavy cargo, raw materials, and freight within operational sites. Customizable lift options ensure compatibility for both shaft and cage installations, supporting unique industrial requirements. Whether you need robust vertical movement in storage or precise goods handling in hospitality, our service adapts to your most specific needs effortlessly.

Payment Terms, Delivery & Domestic Coverage

Handover of maintenance service is handled smoothly with flexible payment terms tailored to client convenience. Upon confirmation, prompt packing & dispatch of spare parts is initiated, with full documentation provided at delivery. Our average delivery time is rapid, ensured by our efficient supply chain. Service is available across India, with coverage reaching all major industrial hubs. Once work is completed, detailed logs and checklists are handed over, ensuring transparency, tracking, and quality assurance.

Diverse Applications & Exceptional Usage

Our Industrial Goods Lift Maintenance Service is ideal for a broad spectrum of sectorslogistics warehouses, factories, storage facilities, and hospitality environments. Highlighted applications include seamless vertical transportation of heavy cargo, raw materials, and freight within operational sites. Customizable lift options ensure compatibility for both shaft and cage installations, supporting unique industrial requirements. Whether you need robust vertical movement in storage or precise goods handling in hospitality, our service adapts to your most specific needs effortlessly.

Payment Terms, Delivery & Domestic Coverage

Handover of maintenance service is handled smoothly with flexible payment terms tailored to client convenience. Upon confirmation, prompt packing & dispatch of spare parts is initiated, with full documentation provided at delivery. Our average delivery time is rapid, ensured by our efficient supply chain. Service is available across India, with coverage reaching all major industrial hubs. Once work is completed, detailed logs and checklists are handed over, ensuring transparency, tracking, and quality assurance.

FAQs of Industrial Goods Lift Maintenance Service:

Q: How often should I schedule maintenance for my industrial goods lift?

A: Maintenance can be scheduled monthly, quarterly, or on-call depending on your usage and lift condition, ensuring optimal performance and safety.Q: What is included in the lift maintenance process?

A: The process covers comprehensive inspections of electrical, hydraulic, and structural elements, lubrication with synthetic grease, spare parts replacement, emergency system checks, and full documentation including service logs and safety checklists.Q: What areas and lift types does the service cover?

A: Our service is available across India, covering factories, warehouses, logistics centers, hospitality, and storage units. We service both shaft and cage-type installations with customizable options.Q: Who performs the maintenance and are they certified?

A: All maintenance is conducted by qualified and certified engineers, ensuring adherence to ISO 9001 and IS Standards for safety and quality.Q: What are the primary benefits of regular lift maintenance?

A: Regular maintenance maximizes lift safety, minimizes downtime, enhances component lifespan, ensures legal compliance, and keeps emergency systems effective.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry